Recently, in the framework of the GoSmart BSR project, Estonian and Polish partners organized a meeting in Bialystok, Poland to meet stakeholders who are potentially interested in further cooperation. Even though entrepreneurs already have a seemingly significant range of support tools and different programs and events for networking and finding new cooperation partners, TIBS is working to improve its system and find new possible ways for cooperation potential of SMEs to build bottom-up based transnational support system for internationalization, smart specialisation and innovation. Innovation brokers, SME-s, clusters and R&D organisations was brought together to visit Metal Processing Cluster, local vocational schools and companies, such as, Bendex and WhiteHill, with the focus on metal processing and digitalization. It was the first time for innovation brokers to bring such diverse parties to a common meeting.

During the visit to Bendex, the guests got acquainted with the processing of regular, stainless and Corten steel as well as aluminium. This company operates with processes like spinning, powder coating and wet coating with aloxite cleaning, multifunctional washing and phosphate coating, sheet bending and rolling, laser cutting of sections, manual and automatic welding.  While visiting Whitehill, the participants got introduced to many dedicated and innovative ideas, especially in the metal and agri-food sector. Besides, the guests could meet the first innovative Vocational Programming School established in Poland by the local IT cluster from Białystok and Zaklad Doskonalenia Zawodowego in Bialystok (ZDZ) – Vocational Education Centre. “Vocational education is a very important area where we have considerable potential for cooperation. An important area diagnosed is Industry 4.0. Cultural proximity cannot be overestimated, as well as a similar perspective on cooperation within the European Union or our neighbours from Belarus, Russia and Ukraine, or countries such as Georgia or Kazakhstan,” said Sebastian Rynkiewicz, CEO of Metal Processing Cluster. The meetings allowed the participants to confirm the belief that the proposed directions of cooperation activities related to smart specialisations are the most appropriate.

While visiting Whitehill, the participants got introduced to many dedicated and innovative ideas, especially in the metal and agri-food sector. Besides, the guests could meet the first innovative Vocational Programming School established in Poland by the local IT cluster from Białystok and Zaklad Doskonalenia Zawodowego in Bialystok (ZDZ) – Vocational Education Centre. “Vocational education is a very important area where we have considerable potential for cooperation. An important area diagnosed is Industry 4.0. Cultural proximity cannot be overestimated, as well as a similar perspective on cooperation within the European Union or our neighbours from Belarus, Russia and Ukraine, or countries such as Georgia or Kazakhstan,” said Sebastian Rynkiewicz, CEO of Metal Processing Cluster. The meetings allowed the participants to confirm the belief that the proposed directions of cooperation activities related to smart specialisations are the most appropriate.

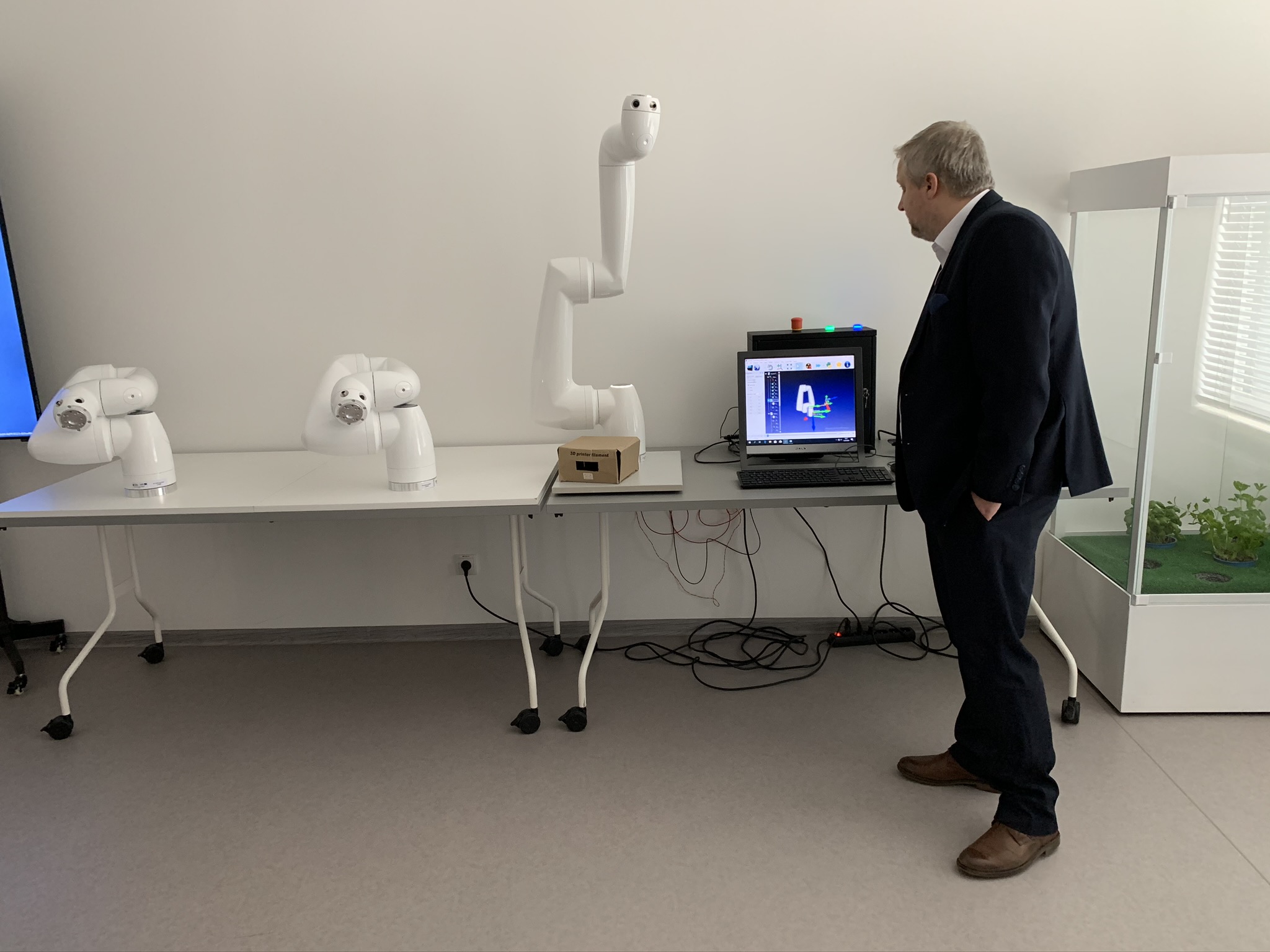

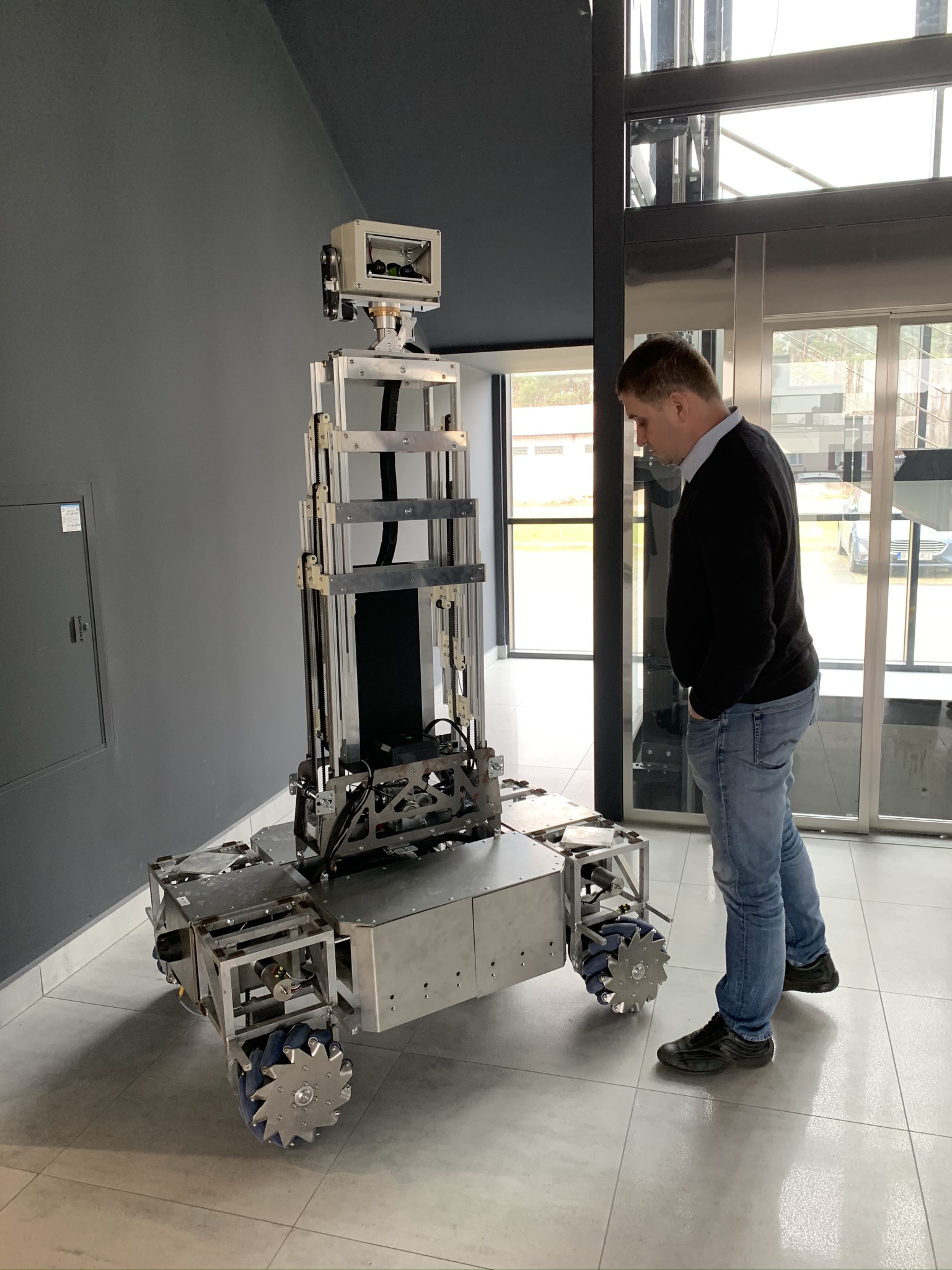

Jüri Riives, board member and development manager of IMECC (Innovative Manufacturing Engineering Systems Competence Centre) and lecturer in TalTech – Tallinn University of Technology, gave an overview of IMECC activities and the importance of digi-analysis. Riives believes that digi-analysis should be carried out in all manufacturing companies, because it reflects the company’s needs for changes and solutions for those. Digital manufacturing helps to improve the company’s efficiency and respond to changing customer demands in a more agile manner. Sigitas Besagirskas, coordinator  of Circular Economy Cluster, gave a short presentation about circular economy, during which, its importance on future economies was highlighted. “The main benefits that circular economy can offer for businesses range from a more attractive image of themselves while capturing opportunities for increased growth, to a gained competitive advantage that includes cost saving. These are the main drivers of circular economy transition, thus businesses should consider the possibility to implement these solutions and this event was a perfect opportunity to discuss a possible collaboration with the representatives of various business companies and clusters,” said Besagirskas.

of Circular Economy Cluster, gave a short presentation about circular economy, during which, its importance on future economies was highlighted. “The main benefits that circular economy can offer for businesses range from a more attractive image of themselves while capturing opportunities for increased growth, to a gained competitive advantage that includes cost saving. These are the main drivers of circular economy transition, thus businesses should consider the possibility to implement these solutions and this event was a perfect opportunity to discuss a possible collaboration with the representatives of various business companies and clusters,” said Besagirskas.

The participants had the opportunity to meet international partners and exchange experiences both as part of official meetings and workshops, but also during the informal networking, giving them space to get to know each other and build trust. “We have been working with partners from Lithuania for years, with colleagues from Latvia less intensively, while Estonia is a new experience for us. We are positively surprised by how much we have in common both culturally and economically.

Industry 4.0 solutions are an area that we can undoubtedly explore together,” added Rynkiewicz. “If the flow of knowledge goes both ways, we are dealing with a classic win-win situation for both sides.” It is an invaluable source of information both in terms of seeking the good practices and learning from someone else’s mistakes. While companies are more willing to share their successes for marketing and PR reasons, sharing experience from mistakes is not easy for everyone.

Garri Raagmaa, director of University of Tartu Pärnu College, expressed regret that it was not possible to meet some of the stakeholders due to Covid-19, hence such meetings help in creating a common space and a sense of cliquishness for the entrepreneurs themselves. „The entrepreneurs can learn from one another, find new partners and sell their products and their region, because business is done by people, not companies,” said Raagmaa.

Wieslaw Urban, the project coordinator, and Jüri Riives wholeheartedly endorse such study trips and consider that those should be organised in the future, while adding that despite the limited time, the meeting was interesting, effective, and valuable contacts were made. It was also emphasised that more work needs to be done with the close neighbours, hence it is very important to know what is happening in the regions and to find opportunities for joint projects. “Of course, you can also work with more remote regions, but the fact is that it is easier to cooperate with the neighbouring regions. This study trip was the seed of several new collaborations,” Riives said.